There are many factories can produce inflatable SUP board in China,but the quality is quite different,because they use the different drop stictch materials,different workmanship,of course,cheap materials with easy workmanship and domestic glue can cut the cost a lot,and offer a unreasonable price,which give illusion to the foreign clients that ISUP is worth that amount only.

But a good SUP board can be the work of art,clear seam,smooth rail,no bubbles,standard rocker,nice pattern for deck pad,premium backpack,etc.Why are they good?Because we invest much more manual work.

There are two methods to produce inflatable sup board:

First method,we call it the old one,which is used by most of the factory who produce cheap board.It is working like this:

1,cut the D.S materials according to the design draft.

2,seal the seam by glue using 8cm wide,0.9mm pvc and inflate it

3,cover the top and bottom of inflated D.S materials by 0.7mm PVC layer by hand,this process can help them to correct the rocker

4,cover the seam with 3cm wide PVC tape

5,Fix the Eva deck pad and D-rings,fin system.

Advantage of this old workmanship:simple and low cost

Disadvantage:Low quality

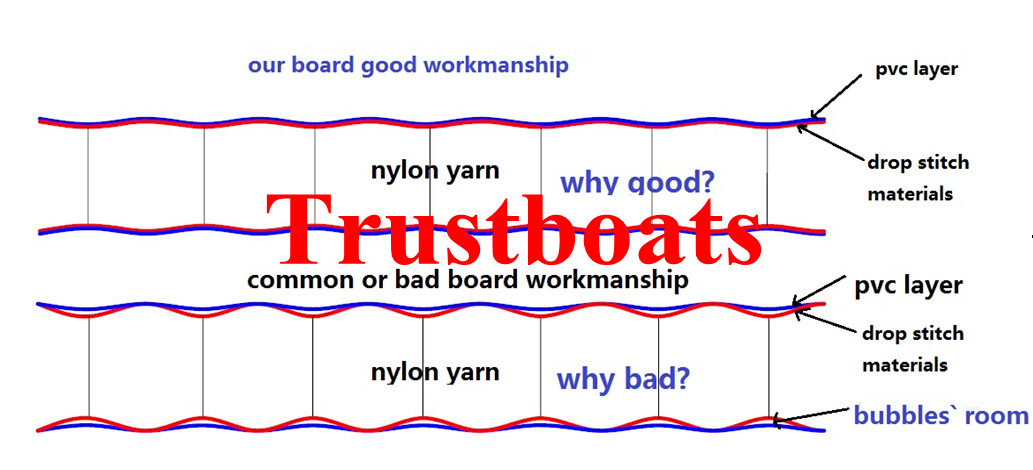

1,It happens on the third precess,after been inflated,there will be many pits on the surface of the D.S materials pulled by the yarns inside,when you cover the top and bottom PVC,there will be many room between the PVC and D.S materials,so when the board is deflated,these room will be the bubbles,there is air in the room.

2, after the pvc layer is glued on the top and bottom of the D.S materials,the extra edge of the pvc is not easy to be trimmed,even it will be covered by 3cm PVC tape,the trail is still ugly.

3,the rail is single layer,easy broken

4,the D.S materials is 1.0mm,and sealed rail pvc is 0.9mm,both are not soft,and their glue area is 1.5-2cm wide only,so in more than six month using,the possibility of leaking is very high.

Second method,we call it advanced workmanship,which we are using now:

1,cut the D.S materials according to the design draft.

2,glue the top and bottom by 0.7mm PVC layer by machine,and trim the edge.

3,seal the seam by glue using 8cm wide,0.52mm soft PVC and inflate it,this proces correct the rocker.

4,cover the rail with extra 10cm wide,0.9mm PVC tape

5,Fix the Eva deck pad and D-rings,fin system.

Advantage of advanced workmanship: Premium board

1,no bubbles on the surface,because there is no room for air between the PVC layer and D.S materials.

2,the seam is sealed by 0.52mm PVC firstly,it is very soft,so the seal effect is perfect,no possibility for leaking.

3,the rail is double layers,much stronger than single layer.

4.the trail of seam is very smooth,very nice.

Disadvantage:

need much more manual work on correcting of the rocker,that why we are little expensive